Automation from Set-up to Analysiss

The SH800S provides the highest level of automation and ease of use available in a cell sorter. Researchers can accurately set up, calibrate, and monitor sorting with a push of a button. This delivers true ease of operation to save time and improve consistency of results.

A novel microfluidic sorting chip uses patented CoreFinder™ technology to automate key steps of instrument setup and operation, streamlining workflow.

The system is versatile, allowing researchers to sort of a wide range of cell sizes to accommodate application requirements. Chip sizes include 70 μm, 100 μm, and 130 μm.

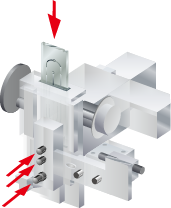

Automated Chip Loading and Positioning

System set-up begins with a one-touch install to load the microfluidics flow cell chip. Actuators ensure precise positioning of the chip inside the chip loader. Sheath, sample, and vacuum lines connect and seal automatically to their respective ports once the chip is loaded. Made of durable plastic, the chip is easy to replace when needed.

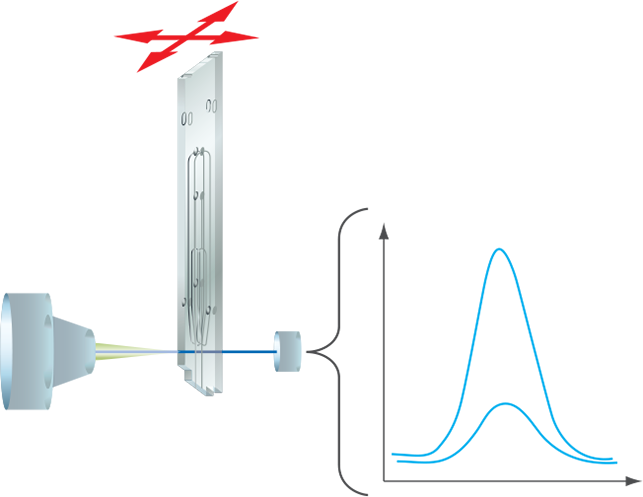

Automated Optical Axis Adjustment

The alignment of the chip to the lasers is optimized automatically during setup using the Sony patented Blu-ray™ technology for aligning and tracking laser position. On a daily basis, using AutoSetup beads, the X and Z positions of the chip are adjusted to ensure consistent results.

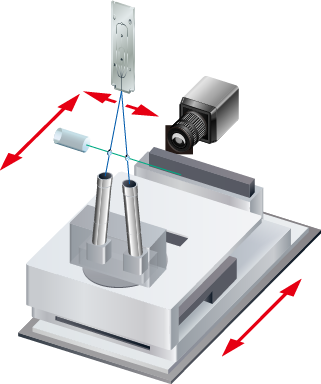

Automated Side Stream Calibration

The angle and the position of the side streams are calculated and adjusted during setup for tube and plate sorting. This ensures that the sort stream is centered in the collection tube automatically without manual adjustment.

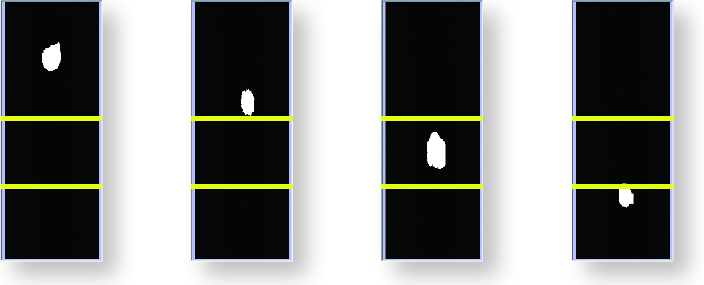

Automated Drop Delay Calibration

A dedicated laser and camera perform real-time analysis of droplet images using AutoSetup beads. Patented technology calculates drop delay by capturing the fluorescence image of the drop-delay beads. The relationship between bead posiitions and drop delay is used to calculate the optimal drop-delay to enable precise targeting and high yield. Automatic analysis of the binary image of the droplets, in real time, calculates the drop delay using a patented algorithm.

Automated Sort Monitoring and Droplet Calibration

The SH800S software monitors and actively makes adjustments to the drop drive to maintain a stable breakoff point. This feature ensures consistently good sort performance and allows detection of clogs and empty tubes, and facilitates walk-away operation.

The droplets are automatically calibrated by adjusting the frequency and the drop drive to achieve optimal break off point (BOP) for each type of sorting chip.

Sort Monitoring

Droplet Calibration