Startup automation ensures optimal daily alignment of the chip to lasers

With the highest level of automation available on any cell sorter, the MA900 uses sensors, software, and engineering know-how across the workflow from startup to aseptic cleaning, QC, and sort setup. Intelligent automation dramatically simplifies operation and streamlines troubleshooting.

Initiation

Upon startup, the software initiates connection between all subsystems and runs diagnostics that ensure that everything is working properly. Once the subsystems are verified, the software displays status and a green ready message on the instrument’s LCD monitor.

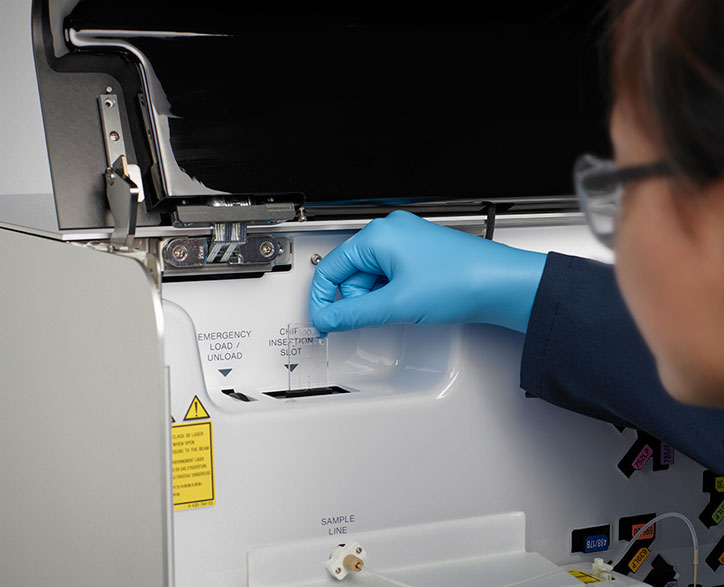

Automated Chip Loading and Positioning

System setup begins with a one-touch installation to load the microfluidic flow cell chip. A setup software wizard guides you through the process of loading a sorting chip, selecting lasers, and inserting the optical filters required. Actuators ensure precise positioning of the chip inside the chip loader. The microfluidic sorting chip uses patented CoreFinder™ technology to automate and streamline key steps in the workflow including chip alignment and accurate calculation of the laser delay, drop delay, side stream angle, and breakoff position.

Once the chip is loaded, the fluidics check starts, and sheath, sample, and vacuum lines connect and seal automatically to their respective ports.

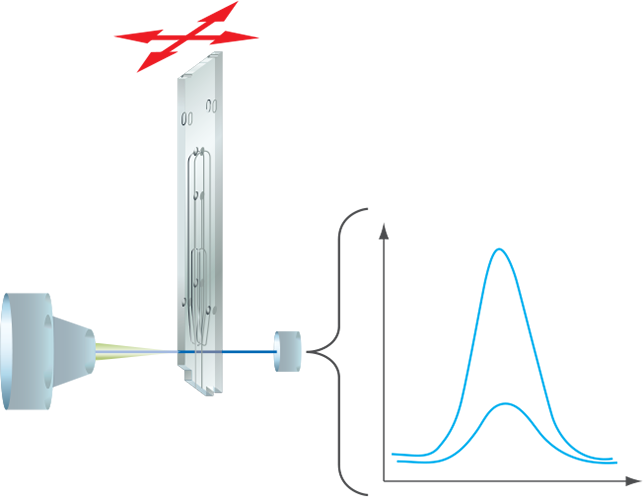

Automated Optical Axis Adjustment

The alignment of the chip to the lasers is optimized automatically using patented technology. AutoSetup beads are used daily to adjust the X and Z position of the chip to ensure consistent results.

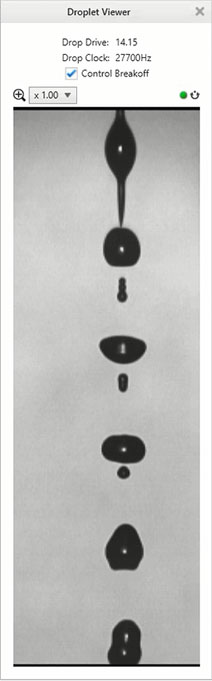

Automated Droplet Calibration

The droplets are automatically calibrated by adjusting the frequency and the drop drive to achieve an optimal breakoff point (BOP) for the 70-μm, 100-μm, and 130-μm sorting chips.

Automated Side Stream Calibration

The angle and the position of the side streams are calculated and adjusted during setup for tube and plate sorting. This ensures that the sort stream is centered in the collection tube automatically.

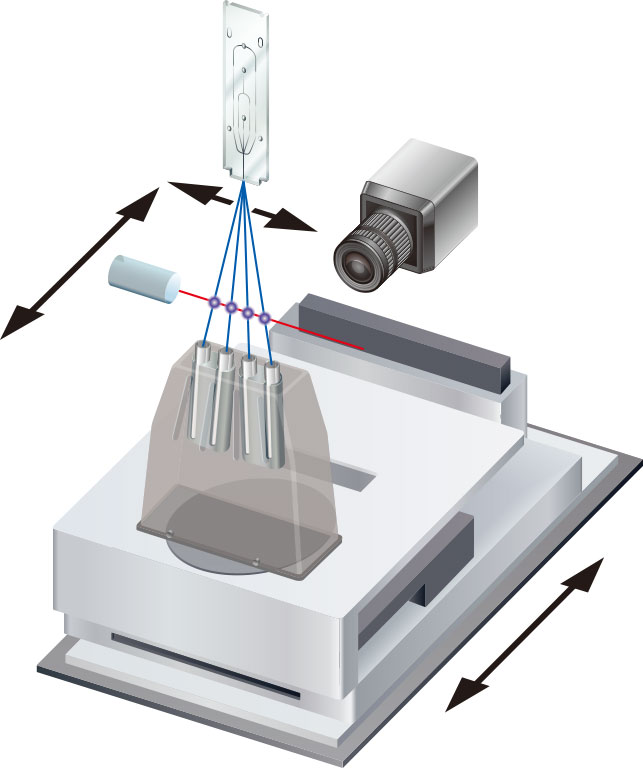

Automated Drop Delay Calibration

A dedicated laser and camera perform real-time analysis of droplet images using AutoSetup beads. Patented technologies calculate drop delay to enable precise targeting and high yield.

Automated Quality Control

Using QC beads, the rCV and linearity are measured and can be displayed in Levey-Jennings plots. This information helps administrators accurately assess optical performance over time.

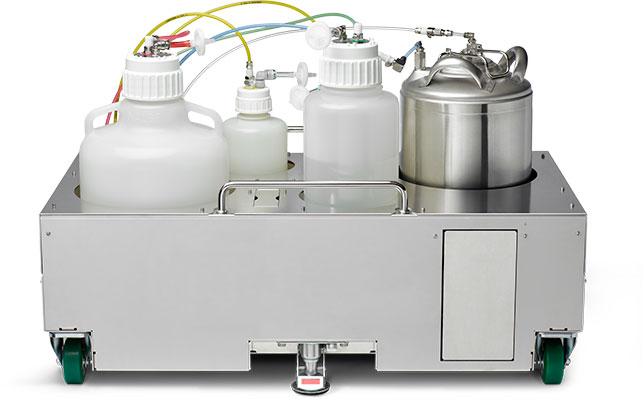

Automated Fluid Sensing

The fluidics cart houses autoclavable sheath, deionized water, and waste tanks as well as tanks containing bleach and ethanol. Weighted sensors on the fluidics cart allow a real-time measurement of the fluid levels, which is displayed in the software.

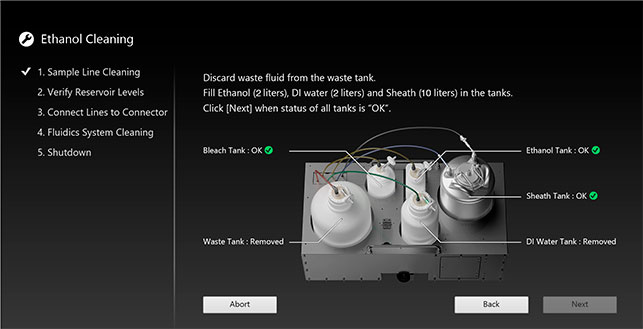

Wizard-Driven Cleaning Cycle

Software guides the operation of default and custom fluidic system cleaning. Default cycles include cleaning with bleach or ethanol. Software guides you through each step of the selected cleaning cycle. Fluid is pumped from three cleaning tanks via a cleaning chip. The software also supports user-defined protocols for setting the time for cleaning. In addition, cleaning reminders can be set up by administrators for convenience.